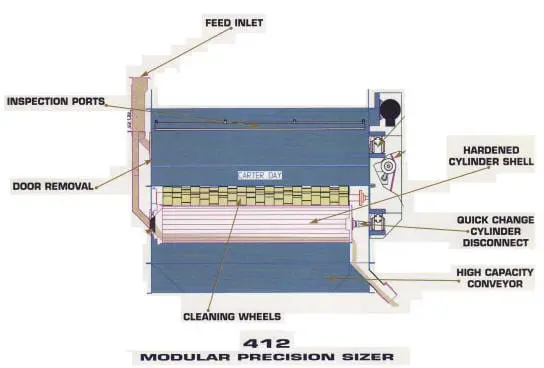

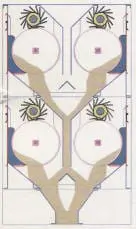

Carter Day Precision Sizers / Graders

Specifications

The Carter Day Precision Grader / Sizer provides methods of sizing or separating various grains and other granular materials by thickness and by width with exactness and uniformity. They can size and separate seed corn, sunflower, barley, wheat, oats, rice, shelled peanuts, soybeans, seeds, and other free-flowing granular material.

Features:

-

Quick cylinder disconnect for easy change or cleaning means less down time.

-

Can utilize all types and sizes of cylinder openings for a wide range of applications.

-

Simple and smooth operation for less down time and easier operator control.

-

Capable of 24 hour operation.

Specifications:

Model 1VT: 21"w x 82"L x 35" H, 1/4 hp, 600 lbs.

Model 212: 33"w x 84"L x 45"H, 3/4 hp, 1260 lbs.

Model 412: 33"w x 84"L x 69"H, 1 hp, 1870 lbs.

Model 612: 33"w x 84"L x 93"H, 2 hp, 2596 lbs.

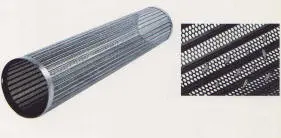

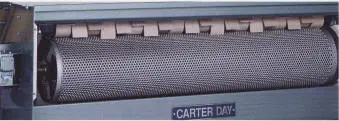

About the Cylinders:

The rotating cylinders present the material to the greatest amount of screen area in the least amount of time for better separations at high volumes. Rotating wiper blades are located at the top of the cylinders where near-sized material is gently pushed back down into the cylinder without damage to the seed.

Every Precision Sizer is self-cleaning. Each cylinder is also designed with a quick change feature for easy changing of cylinders or for cleaning. Numerous styles and perforation sizes are available for a wide range of applications.

Round ribbed cylinders have ribs that run the length of the cylinder between each of several rows of round perforations. These ribs provide gentle agitation that up-ends the material for proper presentation to the perforations. Best for separating small particles by width.

Funlsizer cylinders have funnel shaped round holes. The funnel design up-ends the grain directly into the hole and either allows passage through the hole or rejects the grain and passes it down the cylinder. Best for separating large particles by width.

Slotted cylinders have rectangular slot perforations with indented grooves. Best for separating particles by thickness with close tolerances.

Tri-bar slotted cylinders can double the cylinder capacity depending on slot width. It operates by using a triangular shaped wire, instead of punched slots, producing more open area. Rigid construction maintains opening tolerance longer. Best for separating particles by thickness with high capacity.