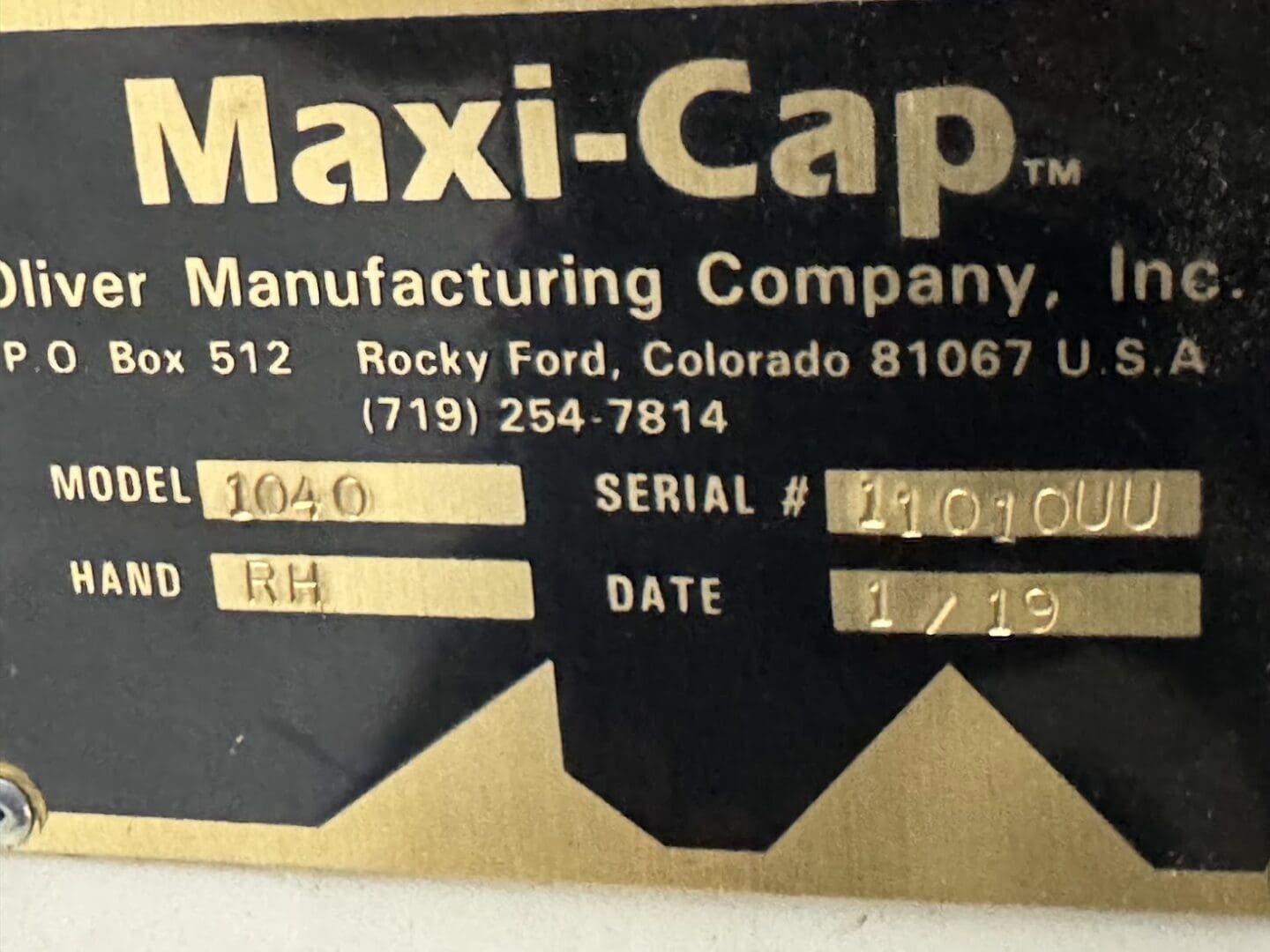

Oliver Voyager 1040 Gravity Table Density Separator

Specifications

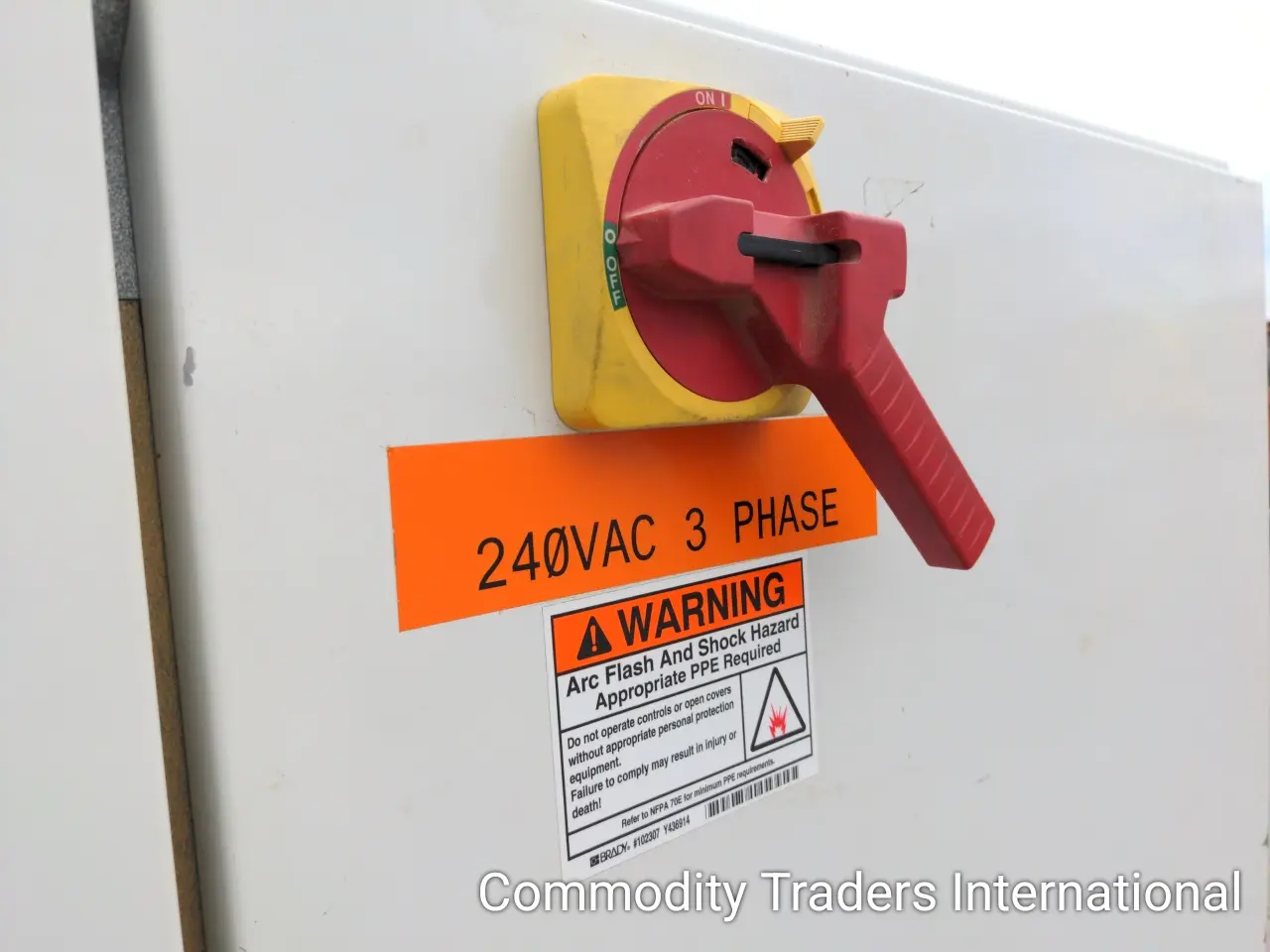

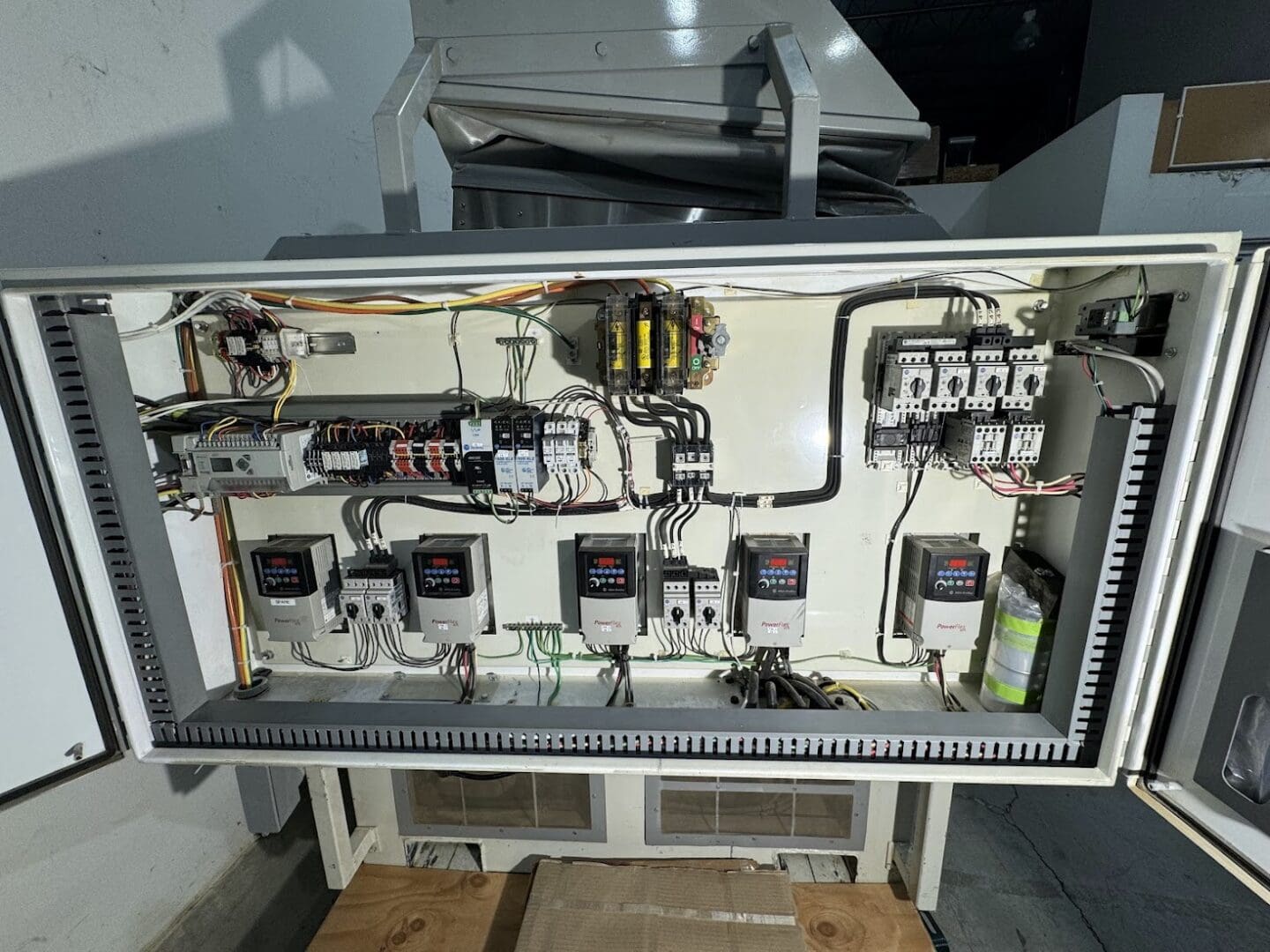

This unit is set up for 230 volt three phase. This machine has a fine wire mesh deck. Please see pictures and video for more details.

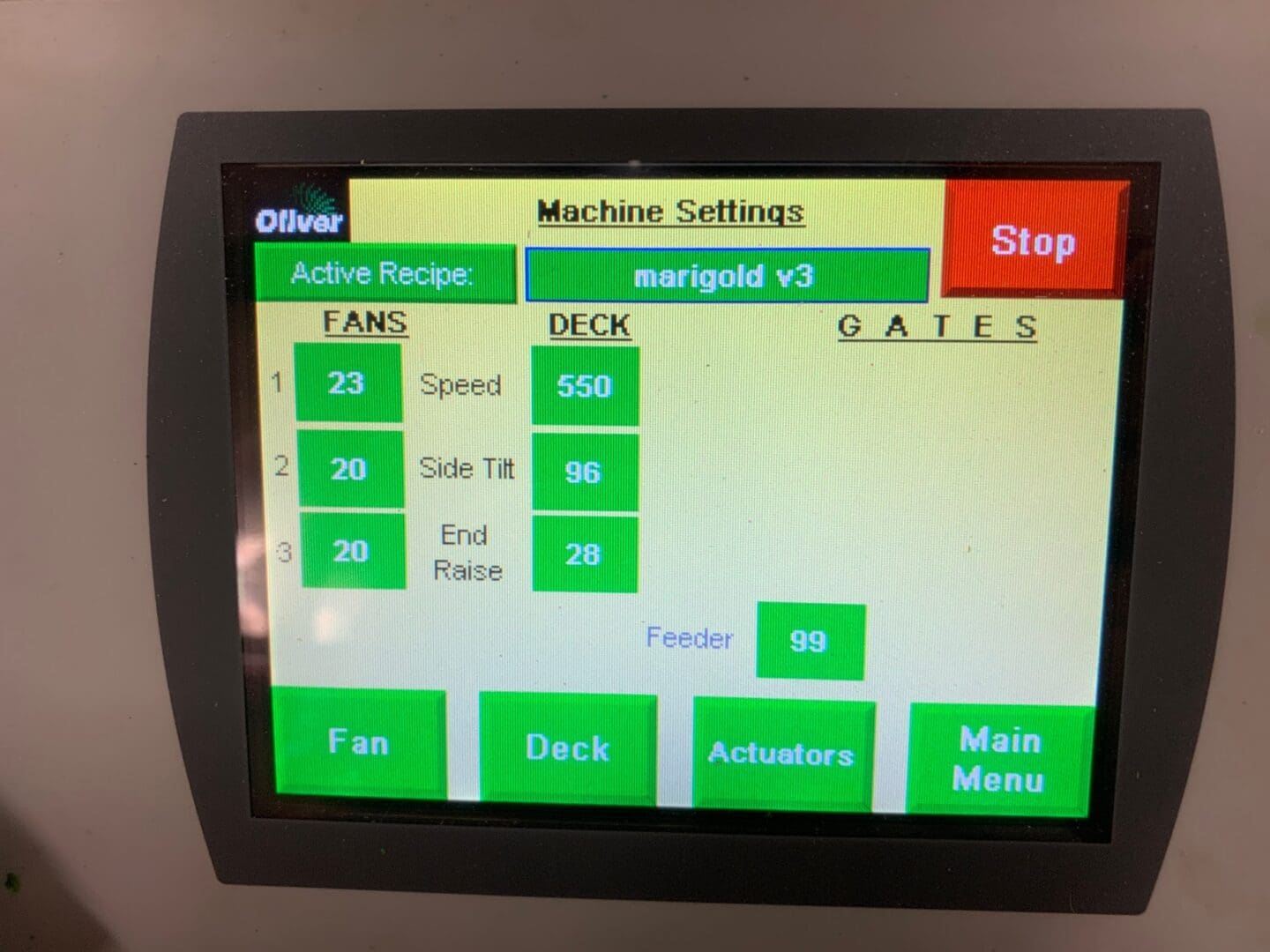

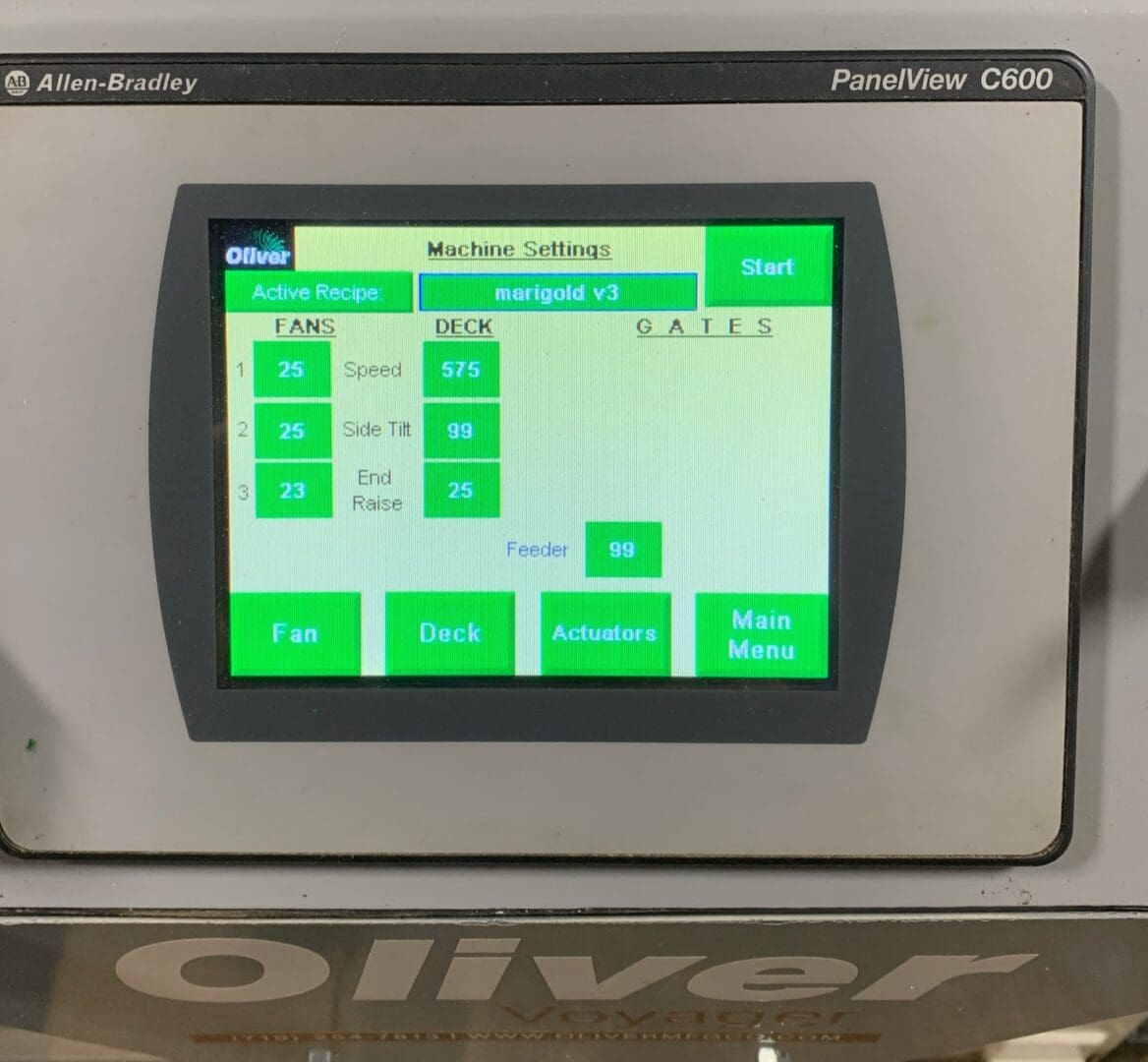

Previous customer used it to separate jasmine and marigold flower petals from rocks, seeds and lighter material like hair or dust. Very adjustable, and they never ran anything heavy like rice or beans or grain on the screen. Screen was cleaned from underneath every 1 to 2 weeks even if only ran for 10-20 hours that week. The machine was in use for R&D lab scale up, so once scaled up it was not in use. Low hour machine

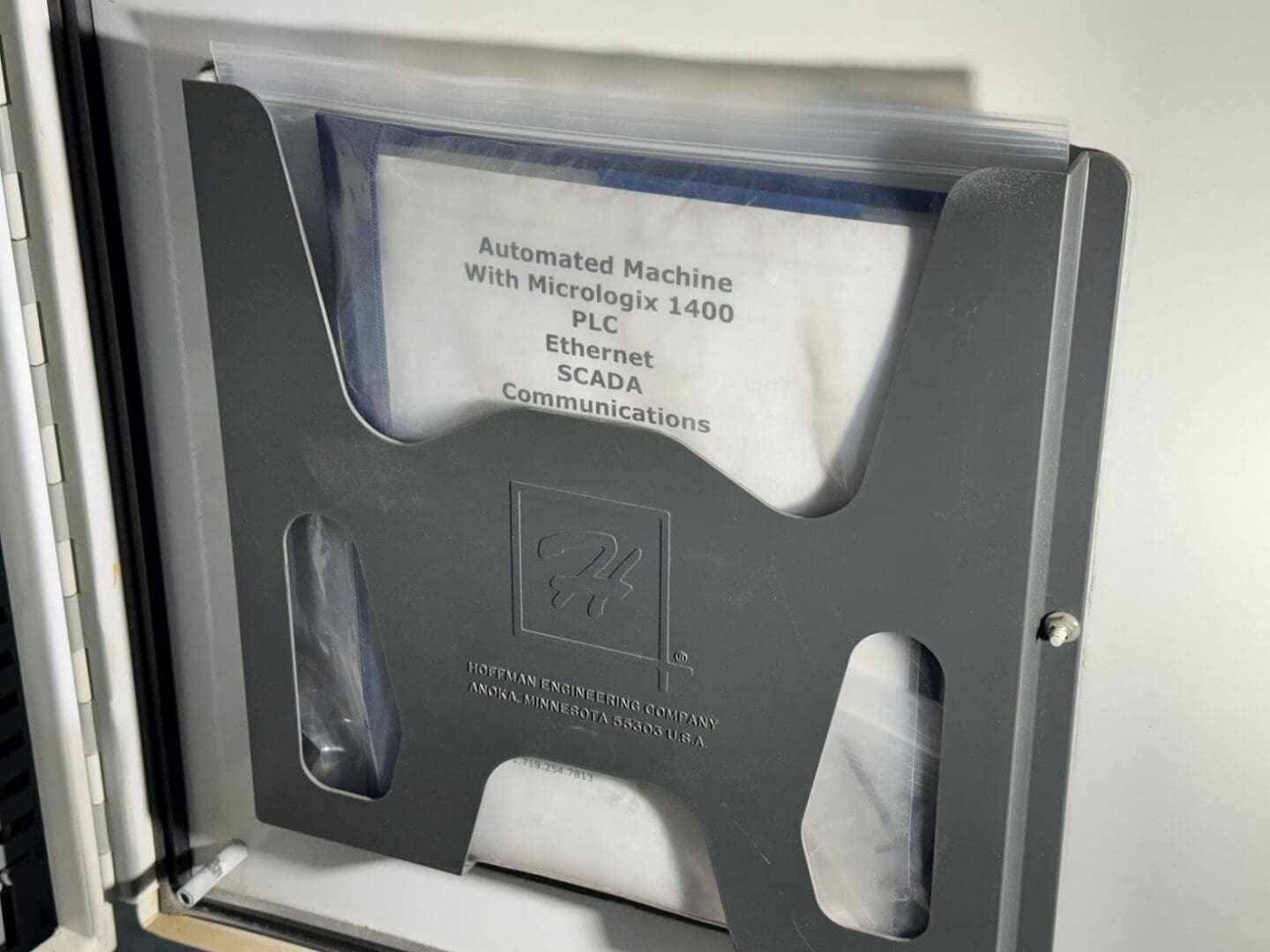

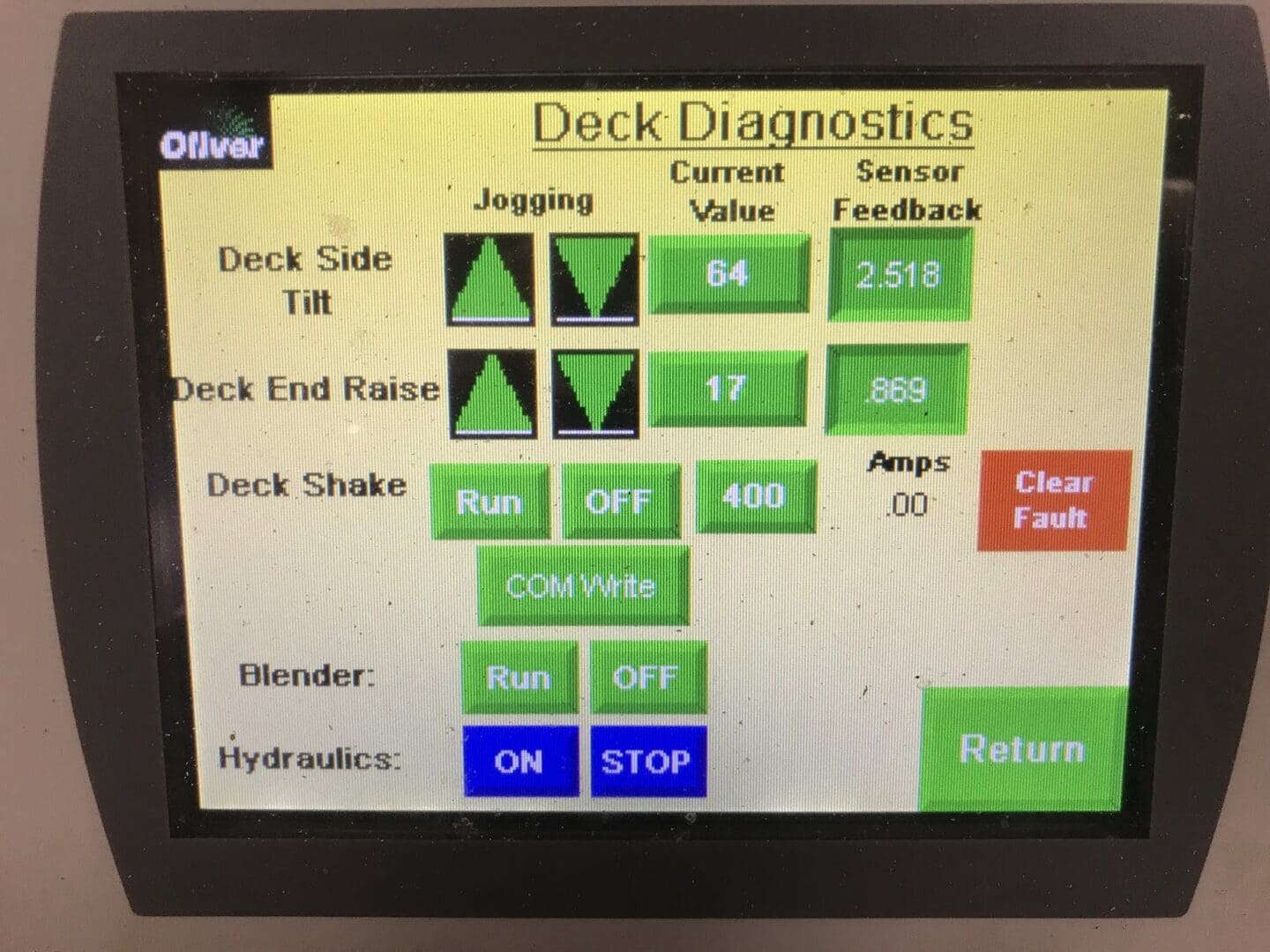

The automation was great with the PLC as an untrained operator could change operatations etc

It has local or remote control, the E stop was wired to a remote system. OLIVER sold the unit with no E STOP, they used that to convey a signal to an external controller that told the voyager to stop. it was not sold with a e-stop so it is not hooked directly to the system. You would push stop on the HMI screen to control everything.

The actuator arm was attached to the feed inlet. It was removed because previous customer just wanted it open but it needs to stay wired up or it has a error. The new owner can install it or not depending on what they want.