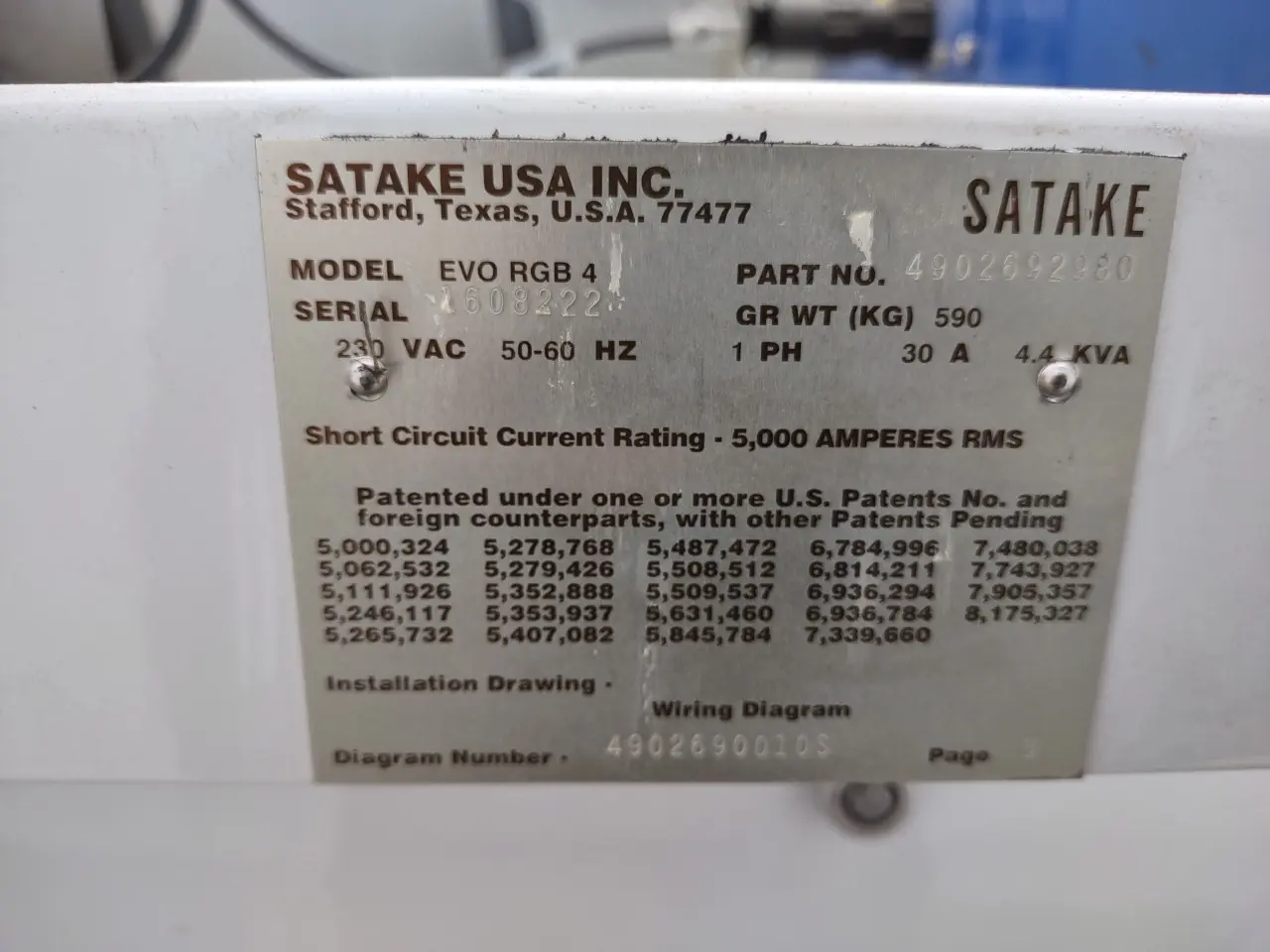

Satake Color Sorter – model EVO RGB 4

Specifications

Evolution model

approx 200 bph / 4 chutes

full color / RGB

DESCRIPTION

Both the human eye and the EVOLUTION RGB detect color through three wavelengths (red, green and blue), allowing the sorter to match the eye’s ability to see true color. The EVOLUTION RGB uses 16 million color, high-resolution cameras and long lasting LED lighting to detect and remove defects. It works like the human eye – the smallest color deviations are identified and rejected. It also uses size and shape sorting to remove challenging defects of the same color.

The EVOLUTION MIR (Multi-wavelength Infrared) optical sorter uses numerous bands of IR to detect to remove the highest level of foreign material and other rejects that color and shape may not detect. The MIR is an excellent choice for superior sorting performance from a high-level, high-capacity infrared sorting platform.

APPLICATIONS

Agriculture – Tree nuts, peanuts, edible beans, coffee beans, corn, maize, soybeans, pulses, vegetable seeds, plastics, wheat, barley, chickpeas, etc.

Bulk Solids – PET flakes, plastic regrind and flake, virgin and recycled plastics, pellets, metals, minerals and other bulk solids.

EVOLUTION SERIES: SORTING SOYBEAN FOR COLOR AND SHAPE

A Satake applications engineer demonstrates how the Satake EVOLUTION RGB+Shape optical sorter handles incoming soybean product at 5,000 lbs/hr per chute inspecting each seed for color and shape variations.

EVOLUTION SERIES: DARK HILUM DETECTION ON SOYBEANS

A quick discussion and demonstration on how the Satake EVOLUTION RGB optical sorter (and other similar machines) detect the dark hilum spots on soybeans, and the challenge of fully viewing the product.

EVOLUTION BENEFITS:

The RGB full-color series is ideal for multiple colored applications or minor shade differences.

The MIR sorter line is configured to remove defects in the tough to monitor IR wavelengths.

Combining both the full-color RGB and multi wavelength IR technology provides industry-standard detection.

Proprietary image capture processing software with ability to pinpoint defects and remove them accurately.

No lamp or optical filter change required during product changeover.

Improved high capacity material handling system, up to 50% more capacity.

High ejector density design for concentrating the rejected fraction.

Movable screen to observe the defect image data during product set up.