LMC – Lewis M Carter Manufacturing

Home > New Equipment > LMC – Lewis M Carter Manufacturing

Specifications

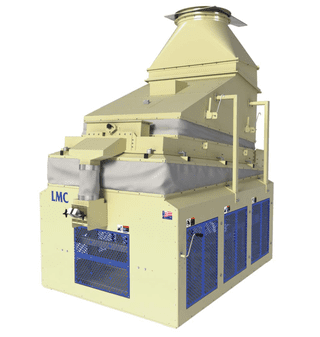

Gravity Separators

The LMC Marc Gravity Separators are the the leaders in making fine, definite separations. The Marc’s balanced construction, low noise, and ease of operation have put it at the top of gravity separators. It is the only gravity separator with an automatic discharge system.So whether you are removing dead seed and weed seed in seed conditioning systems, removing foreign material and damaged nuts in nut processing systems or separating different density plastics in recycling, the Marc shines. Anywhere there is a need to remove less dense contaminants from a product, the Marc is the machine you need.

The ripple deck design gives the deck covering more traction for the separation process. A more complete and distinct product separations is achieved. The automatic discharge system senses product depth and adjusts the discharge gate for fluctuations in product flow. This consistent bed depth eliminates constant readjustments. Multi-lights adjustable gates enable precise control when adjusting light product discharge. A greater bed depth than other gravity separators actually allows LMC’s Gravity Separator to use the product to make more precise separations.On the deck recirculation eliminates the need to have middle cuts. Middle cuts, with more handling, increase product damage. Gone are the blends seen on other gravity separators. The fluidized bed is created single a single super-quiet high efficiency fan. Three component deck system (Deck Cap, Insert, Diffusion Plate) allows for easy change between product changes and sanitation.

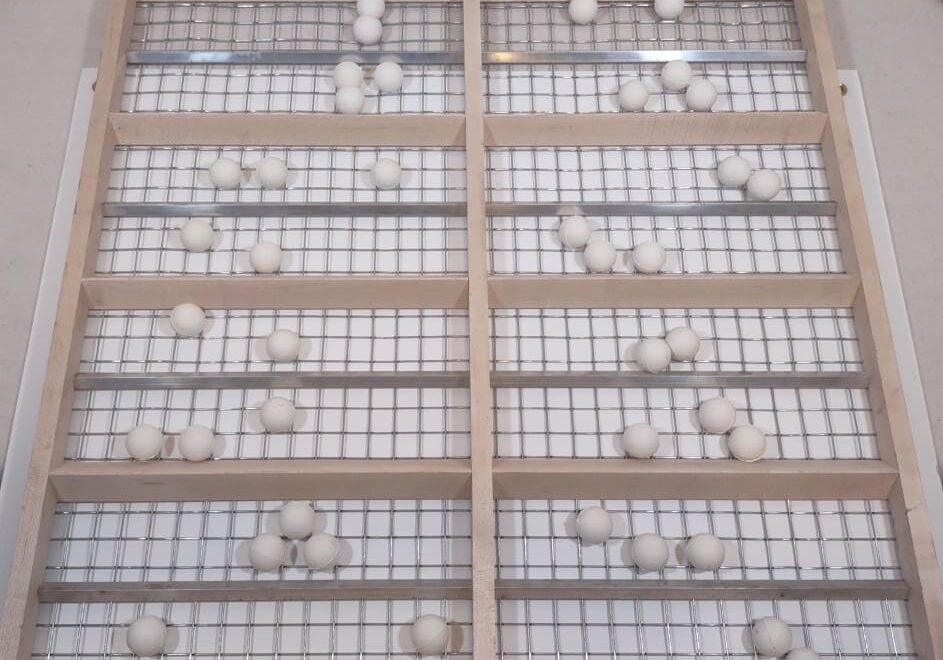

Destoner

The LMC Stoner has a reputation for being the most reliable, user-friendly and efficient stoner available. The heavy-duty construction offers years of service life with minimal attention. No other stoner can match the ease of operation of the LMC. An exact separation can be achieved with a few simple adjustments.The LMC Stoner is designed with food quality construction standards in mind. The three-component deck system (deck cap, insert, diffusion plate) is designed for easy removal when changing products or performing routine sanitation. Sanitary design is particularly important in today’s processing environment where customers are continuously changing between products or varieties. LMC offers several different product contact materials for total customization in order to ensure adherence to the customer’s food safety specifications. An array of options such as stainless steel contacts, dust hoods, VFD controls, and multiple deck configuration are offered to suit the needs of every customer. Several different models and sizes of stoner are available o achieve desired capacities. LMC Stoners are currently being utilized in the edible, seed and recyclable industries.

Click here for our Gravity Tables and Destoner Equipment Specials.